After several years spent in the field destroying nests, we have developed and perfected autonomous solutions providing responses to the constraints encountered.

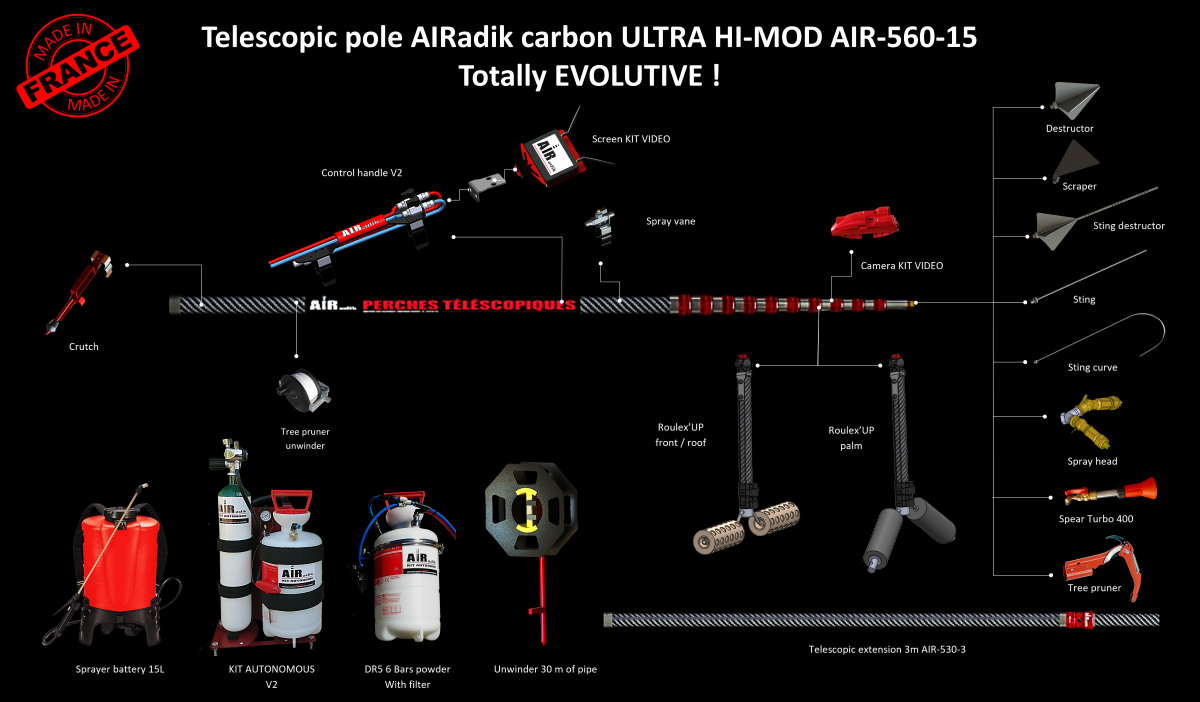

This experience has allowed us to develop a range of telescopic carbon poles for destroying nests of Asian hornets, processionary caterpillars and red palm weevils.

This experience has allowed us to develop a range of telescopic carbon poles for destroying nests of Asian hornets, processionary caterpillars and red palm weevils.

Why choose AIRadik

Specific design

Our telescopic poles have been designed by Asian hornet professionals for professionals. Developed in collaboration with specialists in pneumatic and mechanical design and manufacturing, they are full of technical tricks. Everything is thought to simplify the treatment of a nest. They will allow you to improve your efficiency and thus your performance. Thanks to the time saved, some of our customers now make more than 10 nests in the same day

Telescopic poles made of high quality carbon

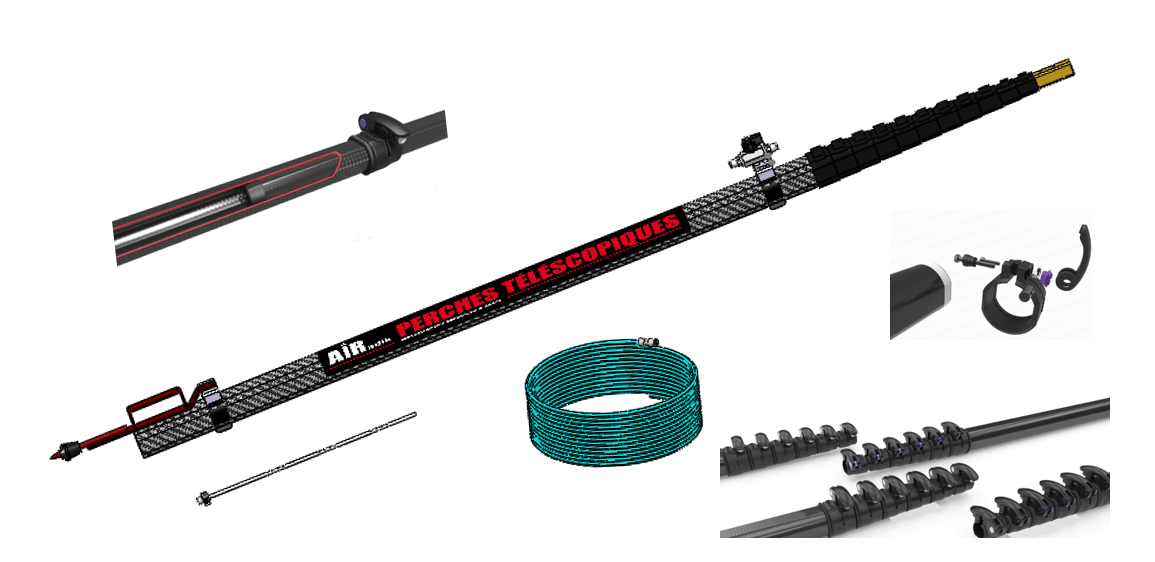

All the tubes that make up our poles and our extensions are custom made in 3K carbon. Due to the fineness and the quality of the threads of this type of carbon, the weaving of these allows to obtain one of the best compromises in terms of strength, rigidity and lightness.

Length unfolded 15 m in one set

Our telescopic poles are composed of 11 tubes, allow to reach the 15 m without any extension which greatly facilitates the deployment of the set.

Low folded length

Due to the small folded length of our poles (2.4m) and our extensions (1.75m), our products can be transported in most vehicles with ease.

1/4 turn aluminum clamping rings

The 1/4 turn rotary tightening principle greatly facilitates pole deployment. In addition, because of their cylindrical shape, no risk of hanging in the branches, indeed no handle or latch exceeds.

Inner pipe

The pipe feeding the tip of the pole is guided and protected inside it. No risk of deterioration or snagging.

Extensions of 1.5 m

The length of our extensions (1.75 m overall, fitting of 25 cm) allows a more practical nesting. This length selected by AIRadik, is the best compromise of practicality. Do not lose sight of it: to fit an extension, you have to hold the pole with one hand and catch the extension of the other to position it. After several tries of length, 1.75 m it turned out to be the best choice.

High quality mechanical parts

All the mechanical parts of our poles are made to measure, cut in the mass by removal of material (machining) which gives them a great precision. Due to their specific design, they ensure a strong tightening in a single quarter turn. The quality of these pieces would be nothing without the use of noble materials. As a result, we have selected high-strength raw materials such as aluminum and brass. Our rings have also undergone a surface treatment to improve sliding between them and make them resistant to corrosion. This is to maximize their service life.

Removable bit

The removable connector at the end of our telescopic carbon-3K pole allows you to quickly change the hose from powder to liquid. For example, you can switch from an Asian hornet powder configuration to liquid "spray" facades or roofs.

Our telescopic poles have been designed by Asian hornet professionals for professionals. Developed in collaboration with specialists in pneumatic and mechanical design and manufacturing, they are full of technical tricks. Everything is thought to simplify the treatment of a nest. They will allow you to improve your efficiency and thus your performance. Thanks to the time saved, some of our customers now make more than 10 nests in the same day

Telescopic poles made of high quality carbon

All the tubes that make up our poles and our extensions are custom made in 3K carbon. Due to the fineness and the quality of the threads of this type of carbon, the weaving of these allows to obtain one of the best compromises in terms of strength, rigidity and lightness.

Length unfolded 15 m in one set

Our telescopic poles are composed of 11 tubes, allow to reach the 15 m without any extension which greatly facilitates the deployment of the set.

Low folded length

Due to the small folded length of our poles (2.4m) and our extensions (1.75m), our products can be transported in most vehicles with ease.

1/4 turn aluminum clamping rings

The 1/4 turn rotary tightening principle greatly facilitates pole deployment. In addition, because of their cylindrical shape, no risk of hanging in the branches, indeed no handle or latch exceeds.

Inner pipe

The pipe feeding the tip of the pole is guided and protected inside it. No risk of deterioration or snagging.

Extensions of 1.5 m

The length of our extensions (1.75 m overall, fitting of 25 cm) allows a more practical nesting. This length selected by AIRadik, is the best compromise of practicality. Do not lose sight of it: to fit an extension, you have to hold the pole with one hand and catch the extension of the other to position it. After several tries of length, 1.75 m it turned out to be the best choice.

High quality mechanical parts

All the mechanical parts of our poles are made to measure, cut in the mass by removal of material (machining) which gives them a great precision. Due to their specific design, they ensure a strong tightening in a single quarter turn. The quality of these pieces would be nothing without the use of noble materials. As a result, we have selected high-strength raw materials such as aluminum and brass. Our rings have also undergone a surface treatment to improve sliding between them and make them resistant to corrosion. This is to maximize their service life.

Removable bit

The removable connector at the end of our telescopic carbon-3K pole allows you to quickly change the hose from powder to liquid. For example, you can switch from an Asian hornet powder configuration to liquid "spray" facades or roofs.

Need a price for a 10, 20 or 30m telescopic carbon pole for destroying Asian hornet nests? Visit our page DEVIS

Always keeping in mind the importance of local manufacturing, a large majority of products AIRadik are designed, developed, manufactured and assembled in the south of France, more precisely in the Tarn and Aveyron.

Rigidité

Why don't we display the GPa value of our poles ?

Why don't we display the GPa value of our poles ?

At AIRADIK, it is true that you will not find the GPa value of our poles.

But for what reason?nbsp;?

Quite simply because we want to be as transparent as possible with our customers.

Indeed, the value in GPa indicated by certain suppliers corresponds to the rigidity of the carbon fiber used for the manufacture of the poles and not to the rigidity of the poles, a marketing nuance...

Short simplified explanation :

A telescopic carbon pole is a set of tubes of different diameters sliding into each other and held together by mechanical elements (clamping rings).

Rigidity is the resistance that a pole will put up to torsional or shearing forces. More commonly, we can image this by the bending of the pole under its own weight.

Maximum rigidity is achieved by the combination of multiple factors. The choice of carbon used for the manufacture of a tube is essential but not only that.

Depending on the need, a carbon thread can contain between 1000 and 48,000 fibers, each of which is approximately 5 to 10 µm in diameter. It is the combination of the quality and the diameter of the fiber which will allow it to obtain the best rigidity.

A tube is made by a skilful weaving of carbon threads linked together using a resin epoxy or polyester.

To manufacture a highly rigid tube, you will have to deal with :

- the quality and diameter of the fiber

- the number of fibers in the yarn

- the direction of weaving/crossing of the threads

- the quality and type of resin to bind the fibers

- the thickness and diameter of the tube

- the tube manufacturing process (filament winding, draping, pullwinding)

- …

We therefore realize here that the rigidity of a tube is due, not to a single element (the stiffness of the fiber expressed in GPa) as some would have us believe, but at least to the various factors above.

The pole being made up of a set of tubes, all these factors must be defined for each of these tubes in order to obtain optimal rigidity.

And since it would be too simple to guarantee a rigid pole with the above elements… there are still the following elements to take into account :

- Fitting length of unfolded tubes

- Clearance between tubes

- Rigidity of clamping rings

- …

To conclude, the extreme rigidity of our poles is obtained thanks to the combination of all the factors cited above, and not only thanks to the GPa value of the carbon fibers...

It is therefore, for example, entirely possible to have a pole made of carbon fibers with a very high GPa value that is less rigid than a fiberglass pole.

If you still wish to know the value in GPa of the carbon fibers used for the manufacture of our poles, do not hesitate to ask us, we will communicate them to you with great pleasure !

But for what reason?nbsp;?

Quite simply because we want to be as transparent as possible with our customers.

Indeed, the value in GPa indicated by certain suppliers corresponds to the rigidity of the carbon fiber used for the manufacture of the poles and not to the rigidity of the poles, a marketing nuance...

Short simplified explanation :

A telescopic carbon pole is a set of tubes of different diameters sliding into each other and held together by mechanical elements (clamping rings).

Rigidity is the resistance that a pole will put up to torsional or shearing forces. More commonly, we can image this by the bending of the pole under its own weight.

Maximum rigidity is achieved by the combination of multiple factors. The choice of carbon used for the manufacture of a tube is essential but not only that.

Depending on the need, a carbon thread can contain between 1000 and 48,000 fibers, each of which is approximately 5 to 10 µm in diameter. It is the combination of the quality and the diameter of the fiber which will allow it to obtain the best rigidity.

A tube is made by a skilful weaving of carbon threads linked together using a resin epoxy or polyester.

To manufacture a highly rigid tube, you will have to deal with :

- the quality and diameter of the fiber

- the number of fibers in the yarn

- the direction of weaving/crossing of the threads

- the quality and type of resin to bind the fibers

- the thickness and diameter of the tube

- the tube manufacturing process (filament winding, draping, pullwinding)

- …

We therefore realize here that the rigidity of a tube is due, not to a single element (the stiffness of the fiber expressed in GPa) as some would have us believe, but at least to the various factors above.

The pole being made up of a set of tubes, all these factors must be defined for each of these tubes in order to obtain optimal rigidity.

And since it would be too simple to guarantee a rigid pole with the above elements… there are still the following elements to take into account :

- Fitting length of unfolded tubes

- Clearance between tubes

- Rigidity of clamping rings

- …

To conclude, the extreme rigidity of our poles is obtained thanks to the combination of all the factors cited above, and not only thanks to the GPa value of the carbon fibers...

It is therefore, for example, entirely possible to have a pole made of carbon fibers with a very high GPa value that is less rigid than a fiberglass pole.

If you still wish to know the value in GPa of the carbon fibers used for the manufacture of our poles, do not hesitate to ask us, we will communicate them to you with great pleasure !

Why use a telescopic pole ?

The different types of solutions for destroying Asian hornet nests are developing, as are the questionable solutions. Find out why using a pole is THE best solution in terms of efficiency, respect for the environment and respect for the law.

Following the arrival on the market of ideal solutions (because patented), the seriousness of our approach and the respect of our customers force us to bring you the following information.

The paintball gun

This gun, simple adaptation of the model intended for the game, does not have a viewfinder. The container containing the balls being positioned on the top of the gun, it is impossible to integrate a target system. As a result, it is relatively difficult to send all the logs into a nest more than 20m apart. As we can see on the different videos on the net, a large number of logs do not reach the nest and fall to the ground.

The balls used consist of a liquid insecticide that spreads very poorly between the trays of a nest compared to powder injected at 6 bar pressure.

This insecticide is, among other things, identified according to the rules (CE) n° 1272/2008 :

- Category 1 (Aquatic Acute 1, H400) Acute toxicity to the aquatic environment

- Category 1 (Aquatic Chronic 1, H410) Chronic toxicity to the aquatic environment

According to the legislation in force, it is necessary to eliminate all residues after treatment. This is to avoid any risk of potential poisoning of the different living organisms present in this area. It is therefore necessary to recover all the balls which have not reached the nest and which are dispersed in the nature. Good luck !

The drone

These noisy devices can scare off hornets and scare away pregnant and working females. It should be known that the relocation of a colony induces the rebuilding of a nest in the immediate vicinity or the recolonization of a treated nest unhooked. According to NOTE DE SERVICE DGAL/SDSPA/N2013-8082 du 10 mai 2013 Extract from the appendix 3 Obligation of result: The provision of destruction of nests of V. velutina is subject to an obligation of result… This failure will force the operator to carry out a new destruction at his expense.

In addition, it seems obvious that the use of a drone for the treatment of a nest positioned in a tree (about 80% of the nests) is very complicated or impossible because of the branches. It would be a shame to crash a drone more than 2000 €.

But also

Regarding these two methods, none of them allow recovery of the nest after treatment. As imposed by MEMO DGAL/SDSPA/N2013-8082 du 10 mai 2013 Extract from the appendix 3 « Chemical destruction: … To limit the risks of secondary poisoning, the stall of the nest should intervene as soon as possible after the action of the insecticide , at most within 72 hours ….

These techniques can be used in addition, when the nests are really inaccessible with the help of a pole.

CONVERSELY

- Our poles allow the use of 100% natural and organic powders as diatomaceous earth for example.

- Equipped with pneumatic secateurs , available as an option, you can recover the nest of hornets after treatment, it can be destroyed according to the regulations in force.

- Our system does not scare or weak the hornets during the intervention. The entire present colony is thus exterminated .

To conclude

The use of a telescopic boom for the destruction of an Asian hornet nest is, to date, THE best solution in terms of efficiency, respect for the environment and respect for legislation.

The different types of solutions for destroying Asian hornet nests are developing, as are the questionable solutions. Find out why using a pole is THE best solution in terms of efficiency, respect for the environment and respect for the law.

Following the arrival on the market of ideal solutions (because patented), the seriousness of our approach and the respect of our customers force us to bring you the following information.

The paintball gun

This gun, simple adaptation of the model intended for the game, does not have a viewfinder. The container containing the balls being positioned on the top of the gun, it is impossible to integrate a target system. As a result, it is relatively difficult to send all the logs into a nest more than 20m apart. As we can see on the different videos on the net, a large number of logs do not reach the nest and fall to the ground.

The balls used consist of a liquid insecticide that spreads very poorly between the trays of a nest compared to powder injected at 6 bar pressure.

This insecticide is, among other things, identified according to the rules (CE) n° 1272/2008 :

- Category 1 (Aquatic Acute 1, H400) Acute toxicity to the aquatic environment

- Category 1 (Aquatic Chronic 1, H410) Chronic toxicity to the aquatic environment

According to the legislation in force, it is necessary to eliminate all residues after treatment. This is to avoid any risk of potential poisoning of the different living organisms present in this area. It is therefore necessary to recover all the balls which have not reached the nest and which are dispersed in the nature. Good luck !

The drone

These noisy devices can scare off hornets and scare away pregnant and working females. It should be known that the relocation of a colony induces the rebuilding of a nest in the immediate vicinity or the recolonization of a treated nest unhooked. According to NOTE DE SERVICE DGAL/SDSPA/N2013-8082 du 10 mai 2013 Extract from the appendix 3 Obligation of result: The provision of destruction of nests of V. velutina is subject to an obligation of result… This failure will force the operator to carry out a new destruction at his expense.

In addition, it seems obvious that the use of a drone for the treatment of a nest positioned in a tree (about 80% of the nests) is very complicated or impossible because of the branches. It would be a shame to crash a drone more than 2000 €.

But also

Regarding these two methods, none of them allow recovery of the nest after treatment. As imposed by MEMO DGAL/SDSPA/N2013-8082 du 10 mai 2013 Extract from the appendix 3 « Chemical destruction: … To limit the risks of secondary poisoning, the stall of the nest should intervene as soon as possible after the action of the insecticide , at most within 72 hours ….

These techniques can be used in addition, when the nests are really inaccessible with the help of a pole.

CONVERSELY

- Our poles allow the use of 100% natural and organic powders as diatomaceous earth for example.

- Equipped with pneumatic secateurs , available as an option, you can recover the nest of hornets after treatment, it can be destroyed according to the regulations in force.

- Our system does not scare or weak the hornets during the intervention. The entire present colony is thus exterminated .

To conclude

The use of a telescopic boom for the destruction of an Asian hornet nest is, to date, THE best solution in terms of efficiency, respect for the environment and respect for legislation.

we talk about us !

The republican EST - firefighters of the Meuse

The republican EST - firefighters of the Meuse

THEY TRUST US

Walloon Agricultural Research Center Government of the Walloon Region

Vidéo of CRA-W visible ICI

Presentation on the Asian hornet of the CRA-W visible ICI

Vidéo of CRA-W visible ICI

Presentation on the Asian hornet of the CRA-W visible ICI

...

Need additional information?